Your Trash Truck Won’t Fit

Compressed Natural Gas (CNG) has seen an increase in use as an alternate fuel source. CNG trash trucks are a common sight throughout the Baltimore area for more than 10 years now. The Baltimore City FD (BCFD) have had several responses involving these types of trucks. The use of CNG provides a cleaner and cheaper alternative to diesel for heavier trucks.

CNG is comprised of mostly methane to provide the clean burn. The key to preparing for a CNG incident is pre-planning, training and continuing education. Preparation for these incidents must also include networking and outreach with the companies running the trucks. These companies can provide expertise, additional knowledge and logistics for making the trucks safe. The trucks use a cascaded system of wrapped fiberglass cylinders that operate at a pressure of up to 3600 psi.

Typical arrangements on trash pick-up vehicles have up to 4 cylinders on the top of the vehicle. The control panel is located on the drivers side close to the ground between the vehicle axles. The valves allow for fueling\defueling as well as controlling the flow of gas to the engine. Drivers are instructed to shut off the flow of gas to the engine in any emergency they encounter.

The trucks use a cascaded system of wrapped fiberglass cylinders that operate at a pressure of up to 3600 psi. Typical arrangements on trash pick up vehicles have up to 4 cylinders on the top of the vehicle. The control panel is located on the drivers side close to the ground between the vehicle axles. The valves allow for fueling\defueling as well as controlling the flow of gas to the engine. Drivers are instructed to shut off the flow of gas to the engine in any emergency they encounter. Most incidents involving CNG trash trucks involve fire. Fires starting in the trash collected are most common. The BCFD has had several of these in the streets of Baltimore. Recognition of CNG being involved is the key to successfully controlling these incidents. Relief valves (fusible plugs operating at 220 degrees) must be allowed to operate without interruption. Exposure protection is a primary response goal until the CNG tanks have emptied. Vehicle accidents can be controlled relatively easily unless specific circumstances exist such as damaged supply lines. Knowledge of the control valves would be essential to control the flow of gas to the damaged lines. First responder training is a must to understand actions to take when encountering these vehicles under fire or accident conditions.

All of the training and preparation described came together in June of 2023 in East Baltimore. A trash truck attempted to pass under a railroad bridge and did not have the proper height clearance. The truck became stuck, unable to move and the bridge supports damaged one of the high pressure cylinders. The cylinder had a slow leak that was audible to crews on the ground. The driver was uninjured during the accident. The railroad bridge struck was a major line in the Northeast corridor of Amtrak service. Rail service from Boston to Richmond was shut down for almost 3 hours while the incident was cleared.

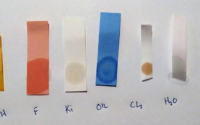

The leaking CNG was migrating up through the openings in the bridge into the path of the trains. The first arriving engine company quickly recognized the scope of the incident, requested a hazmat assignment and isolated the scene. A decision to defuel the cylinders on the scene was made given the cylinder was damaged and could not be controlled by the valves. The trash truck company service crew and flaring equipment from the Maryland Dept. of the Environment was utilized for the operation. A vent operation taking advantage of the lighter than air vapor density of CNG was completed within 45 minutes. Tanks were at 3\4 full at the start of the vent operation. Once the tanks were rendered safe, a local tow company began the process of removing the truck from under the bridge. Railroad engineers were on scene to evaluate the damage to the bridge. Key points to consider from this incident:

- Proactive training and awareness of alternate fuels in your first due. The BCFD has been training with this trash pick up company since 2015. Cooperation has been essential in handling accidents and fires involving their trash trucks.

- Expect the unexpected. CNG incidents usually involve fire. Rare incidents like this one provide a challenge that demands a clear course of action based on solving the problem. A defueling operation was the solution for this incident to render the damaged cylinders safe for salvage.

- Specialized equipment needs. A specific part of the proactive training is recognizing and procuring specific pieces of equipment needed for scenarios such as this. CNG adapters, steel braided hose and flare stands may not be carried by all fire departments or hazmat teams. Purchasing this equipment may not be an option for some departments. The next best option is establishing mutual aid agreements with departments or agencies that can provide this equipment in a timely manner for emergency response. The trash collection company is able to bring us defuel equipment except they have no one available to assist between 2300-0700 as their maintenance shop is closed. Conversely, their trucks don’t run in that time frame however you need to know when your resources are available to you. MD Dept. of Environment is available 24 hours a day although response times can be 1 hour or more. Decision making must be adjusted based on what is available and how long it will take if you cannot provide the specialty equipment from your own department.

Alternate fuel usage is on the rise. CNG, LNG, Battery power and Hydrogen fuels will be seen in emergency response. Emergency responders will have to meet the challenge with proactive measures. The department that is training, planning and adapting will be prepared for the ever changing world of alternate fuels.