Leak and Spill Control on Intermodal Portable Tank Containers

Michal S. Hildebrand, CSP

The recent collapse of the Key Bridge in Baltimore, Maryland was caused by the container ship Dali losing control and colliding with the bridge. If the ship stood upright, it would almost reach two-thirds of the Empire State Building in New York. The ship was carrying nearly 4,700 intermodal containers, on a ship with a capacity of 10,000 containers. This is impressive, but there are even larger container ships with capacities up to 20,000 containers or more. There reports in the news media that some of these containers were damaged, however, there is a big difference between a damaged intermodal container and one that is leaking, as this article will reveal. See Figure-1.

Figure 1 –Many intermodal containers were damaged during the Key Bridge collision, but damage to the outside of the container seldom results in the breaching of packages, drums, etc., inside of the intermodal container. Photo: U.S. Coast Guard.

The advantage of intermodal containers is that they can be shipped by marine, highway, or rail, and the same containers can easily be carried by different means of transportation without any changes or modifications to the containers themselves; they are simply lifted by cranes from one mode of transportation to another. If you have a highway, rail track, or port in your community, you have the potential for an intermodal container emergency.

General Types of Containers

There are two general types of Intermodal Containers:

- Freight Containers – also known as “boxes”, “isotainers”, or “TEU’s” (Total Equivalent Units in 20 or 40 foot standard lengths). Freight Containers are basically tractor trailer type boxes that can transport almost any type of hazardous materials in boxes, drums, totes, sacks packaged inside the intermodal freight container.

- Intermodal Portable Tank Containers – These containers range from food grade liquids like cooking oil and drinking alcohol to all classes of hazardous materials in non-pressure or pressurized containers. They primarily contain liquids, although some intermodal tank containers are designed to transport gases, solids like powders, and cryogenics.

The focus of this article is on the most common types of leaks that emergency responders may encounter involving nonpressure intermodal tank containers for liquids and solids (Hazard Classes 3-9) with T Codes 1 to 22 (IM 101 and 102 and IMO Type 1 and IMO Type 2) described in the DOT Regulations.

Information in this article are based on the textbook Intermodal Container Emergencies, Second Edition, by Michael S. Hildebrand, Gregory G. Noll, and William T. Hand, Burlington, MA: Jones & Bartlett Learning (2018) and are reproduced with permission from the authors and the publisher. See Figure-2.

Figure 2 –The textbook Intermodal Container Emergencies 2nd Ed., covers design and construction features, marking systems, intermodal freight containers, intermodal portable tank containers for liquids and gases, as well as fire spill and leak control techniques.

Most Common Sources of Leaks

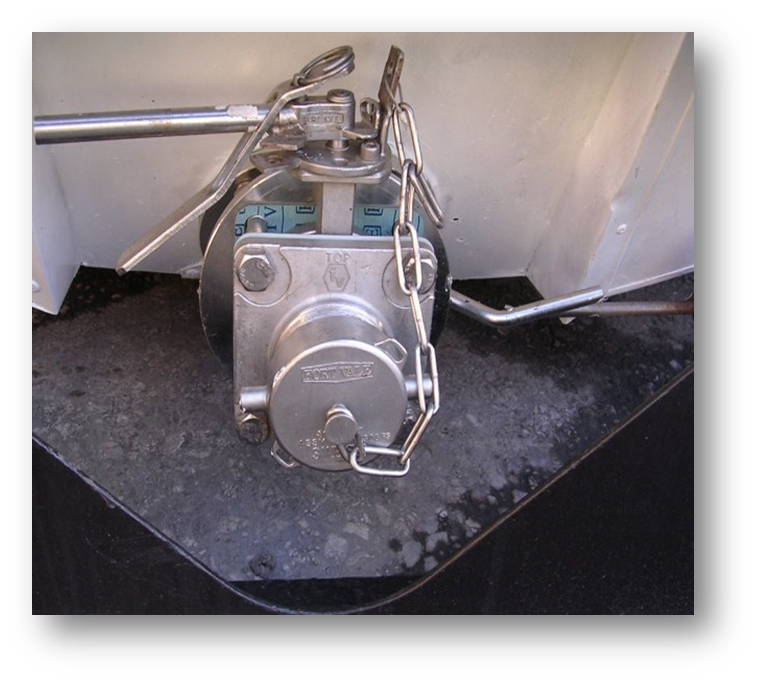

The majority of spill and leak situations encountered on IM-101 and IM 102 (IMO Type 1 and 2 – T Code-1 – T22) tank containers involve loading and unloading accidents. Common scenarios include loose fittings and valves, overfills caused by product expansion, and “mystery leaks” through the tank shell. See Figure 3 A & B.

Figure 3 A&B –The primary source of leaks on intermodal portable tank containers comes from the foot valve (F-3-A-Photo: Guard Europe) found at the bottom of the tank. The valve handle placed across the valve indicates the valve is closed. The photo of the disassembled foot valve shows the butterfly shutoff valve which would be outside the tank shell and the internal emergency shutoff valve. (F-3-B Photo: Qualitank Services).

Overfills – Overfills can be caused when a tank container is overfilled with product without room for expansion. Once the container is subjected to ambient heating after sitting in the hot sun for a while, the product may begin to overflow through the manhole cover or pressure relief devices. In this situation, the container must be cooled to reduce the internal pressure and the effects of the ambient heating. Product may need to be transferred from the container to reduce the potential for the problem to happen again, and burst discs may need to be replaced.

Mystery Leaks – Other common scenarios with tank containers are mystery leaks through the tank shell. For example, liquid might drip from an opening or crack through the insulating jacket in the lower half of the tank. If the tank has not been involved in an accident, the source of the leak is often water from condensation on the tank. If a previous bump or scrape has torn the outer jacket, the inner tank shell may have been exposed to warm air, causing condensation. The insulation between the inner tank and outer jacket becomes saturated with water, and eventually water drips out through openings in the outer jacket. If it is a warm day, the tank has an opening in the outer jacket, and the container has not been involved an accident, you probably have water on the ground. Standard hazmat identification procedures, air monitoring, and sampling usually take the mystery out of the situation. Figure 4.

Figure 4 This intermodal portable tank container has had its outer aluminum jacket ripped open on the end. The outer container shell has been “Damaged”. The inner tank shell has been dented but the shell has not been breached. Note the layer of insulation and the insulation between the jacket and the tank shell. (Photo: Trans Ocean).

Bottom Outlet Leaks – If product is leaking from the bottom outlet valve cap or a blind flange, make sure the cap or flange are tight. Do not remove the valve cap without first checking the position of the valve. The valve handle should be in the closed position— horizontal to the valve. If the valve handle is in the open position (in line with the valve), the remote emergency shutdown handle can be activated to close the internal foot valve. Intermodal tank containers are equipped with a remote shutoff device. The bottom outlet valve can be closed by activating the device.

Container Shell Leaks – Portable tank containers are mounted and attached to a rigged tank frame which protects the container from damage. The tank container is built with an outer shell, usually made from aluminum, and an inner shell. An insulation barrier is often found between the inner and outer shell so protect the liquid contents from the ambient temperature fluctuation. If a tank container is damaged and the inner tank has been breached, the insulating jacket will make leak control tactics very hard. In this way, jacketed tank containers share the same problems as jacketed MC-307/DOT-407 and MC-312/DOT- 412 cargo tank trucks. Figure 5.

Figure 5 This intermodal portable tank containers construction features include a steel frame which holds the portable tank. This tank is usually wrapped in an aluminum shell that displays the hazard markings and holds the insulation around the tank in place. The inner tank shell is made from steel compatible with the tank’s product. (Photo: Tank Global).

If the tank container is a single-shell container, standard leak control tactics and techniques can usually slow the leak. Important factors determining the success of patching and plugging operations will include the pressure of the leak (i.e., higher pressures = less effective leak control operations) and compatibility between the chemical and the patching / plugging device.

Top Fittings and Manhole Leaks – In rollover situations the topside manhole cover may leak because the wing nuts were not properly tightened. These leaks are sometimes caused when the manhole dome cover wing nuts are tightened sequentially in a clockwise direction rather than in an alternating pattern (e.g., the way you tighten lug bolts on an automobile wheel so the rim and tire are straight). Alternately tightening down the wing nuts can sometimes stop the leak. Figure 6.

Figure 6 This shows the spill box on top of a tank container. If the dome cover is leaking in an overturn situation, make sure to tighten down right-to-tight and alternate like you would the lug bolts on a car so the dome seals correctly. Tank overfills are usually first detected from drips or a liquid pool under the tank. Note that the spillbox has a drain to the ground to remove rain water. The leaking liquid may be hazardous cargo or water dripping saturated tank insulation or melting ice on top of the tank. Always test the leak for corrosivity to determine pH. (Photo: Southern Cross Tank Containers).

Summary

Intermodal Portable Tank Containers can take a lot of battle damage because they are attached to and suspended within a rigged steel frame for handling and stacking in transportation. Most accidents do not involve a breach of the container shell, they involve loose fittings and valves, or are simply water leaking from condensation between the inner tank shell and the outer tank shell.

For more information on intermodal container fire and leak control, see Intermodal Container Emergencies, Second Edition, by Michael S. Hildebrand, Gregory G. Noll, and William T. Hand, Burlington, MA: Jones & Bartlett Learning (2018).