Hazards of Carbon Dioxide Dewar Containers in Fast Food-Type Occupancies

Mike Bloski

Carbon Dioxide, commonly referred to as CO2, is a well-known gas, yet not everyone fully comprehends its potentially lethal nature. Being a fraction of the atmosphere, CO2 is typically associated with human exhalation and its application in specialized fire suppression systems. On a commercial scale, CO2 is either produced and transported as a liquefied compressed gas or employed in its solid form, commonly known as dry ice. The greatest hazards are a leak in the supply system of a CO2 system used in beverage delivery. The system uses the CO2 liquid converting it to vapor state to expel the contents from storage syrup bags or kegs.

Traditionally, these systems did not pose a significant threat to firefighters, primarily because of the relatively modest-sized volume of the CO2 cylinders used in such establishments. However, firefighters are facing an escalating risk associated with CO2 due to undetected leaks originating from exterior larger-sized CO2 cylinders or the supply systems used to deliver CO2 to the inside dispensing system. While these leaks remain infrequent, their occurrence appears to be on the rise in commercial settings.

The increase in brewery locations in popular culture increases the potential for more emergencies placing firefighters at greater risk. In addition, to relative non-toxic conditions apparent to responders’, greater safety must be exercised suspecting a CO2 leak problem on any delivery system present. Lastly, CO2 is commonly dispatched as a Carbon Monoxide issue as occupants do not understand local installed systems mistakes are made.

Situational Awareness:

Education at the hazmat operations level should include responding to patients or unknown odors in fast food or local drinking establishments should be aware that they may be responding to a CO2 leak. CO2 is 1 ½ heavier than air and, in the event of a leak in

enclosed spaces, such as walk-in coolers, manager’s offices, restrooms, employee rest areas, and basements, can accumulate quickly. Since CO2 is undetectable by human senses, the only safe way to monitor it is by using fixed or portable alarm systems. Alarms designed for the restaurant industry are available, which monitor the level of CO2 in the air. As CO2 gas is heavier than air, it is recommended that fixed gas detectors be installed at breathing zone level, which is four to six feet above the floor. Employees must be trained in how to respond when a CO2 monitor activates.

Operational Considerations:

Response crews suspecting a CO2 leak must use an SCBA (Self-Contained Breathing Apparatus) while operating in a potentially IDLH atmosphere and should consider calling for a Hazmat teams for response. The use of 4-gas meters to detect oxygen displacement should also be considered, as each 0.10% drop is equivalent to 5,000 ppm atmospheric replacement (IDLH for CO2 is 40,000 ppm). An air reading of 20.0% indicates an IDLH atmosphere. Hazardous materials-trained and -equipped companies typically perform atmospheric monitoring for oxygen, methane, carbon monoxide, and potentially explosive gases by metering for the lower explosive limit (LEL), but they do not monitor for carbon dioxide. When response crews detect low oxygen levels in establishments using CO2, they must consider the possibility of elevated CO2 levels.

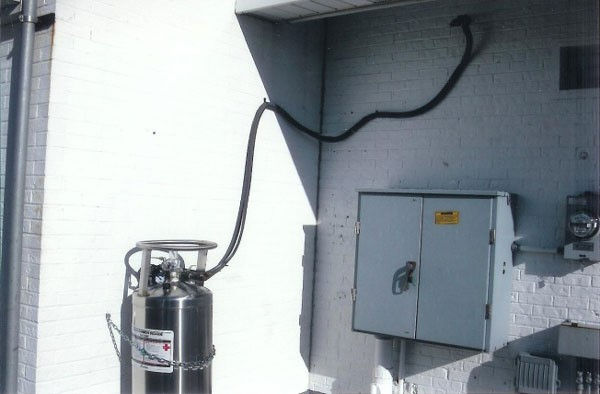

Commercial business CO2 fill valve found on the exterior.

Response Options:

First responders dispatched to a carbon dioxide (CO2) leak in a commercial building should prioritize safety and follow specific response procedures. Here are response options for first responders:

H- Hazard Identification:

- Identify the CO2 supply system either exterior, interior, or both, what type and contents of tanks understanding the plumbing of the system. A thermal imaging camera is beneficial for locating leak sources on cold surfaces and plumbing.

- Begin air monitoring utilizing 4-gas meter inside the occupant checking all spaces with primary search.

- Caution all responders not to make contact with vapor clouds, exterior tank shells, or associated plumbing with the system.

A- Assistance:

- Immediately call for local hazmat response, if necessary.

- Check the tank for emergency assistance contact numbers.

- Work with the occupancy manager on the service company for the source tank. Have them respond to the scene to give technical advice and control of the system.

Z-Zoning:

- Evacuate the structure relocating occupants to safe distance of 330 feet following ERG Guide #120.

M-Manage the Incident:

- Establish Incident Command as needed.

- Establish a command post at least 330 feet from occupancy doors and windows.

A-Action Plan:

- If equipped with proper PPE, identify the source and extent of leak.

- Identify emergency shutoff’s (E-Stops) and valves. Do not turn off valves or processes without technical assistance and advice.

- If possible, go into second round of air monitoring with Carbon Dioxide detectors from Hazmat Team response. Note: the occupancy alarm may only indicate leak and not give responders exact leak condition in parts per million.

- Monitor the system with thermal imager camera noting tank conditions.

- Consider your ventilation plan. Average size of fast-food restaurant is 21,000 cubic feet or greater. This might require 5 minutes of controlled ventilation before getting to 5,000 TWA for CO2.

- A consideration is to locate the cylinders outside the structure if can be done safely.

T-Termination:

- Verify by air monitoring prior to leaving for occupants to re-enter the structure.

- Secure the system until it can be service by a professional repair company.

- Reinforce customer service to call back if conditions change after the response.